Quick Summary

Predictive analytics have improved supply chain efficiency by exploiting available data for better decisions. The ability to predict future demand and identify operation problems helps businesses optimize their organizational processes. Companies cut costs, manage stock better, and improve their shipping processes by using predictive analytics. Firms that put predictive analytics to use tackle business problems and cut down on risks. This allows their supply chains to keep running without any hiccups.

Introduction

Handling supply chains efficiently is a tightrope for organizations as there are multiple tangible and intangible aspects like weather, delays, traffic, fluctuating demand, supplier reliability, geopolitical events, regulatory changes, and unforeseen disruptions that come into play. Gartner’s data survey substantiates this — 76% of supply chain executives see frequent disruptions in their supply chain.

Descriptive analytics helps organizations keep tabs on past patterns. Diagnostic analytics allows them to pinpoint the root causes of problems. They can use prescriptive analytics in their supply chains to suggest the best courses of action. Cognitive analytics employs AI to make smart decisions.

While these analytical methods offer significant advantages, predictive analytics shines. It gives businesses the ability to forecast future demand, see disruptions coming, and make decisions ahead of time.

Let’s discover how predictive analytics transforms supply chains from reactive to strategic operations.

Here’s How Predictive Analytics in Supply Chain Management Transform Businesses

- High supply chain analytics performers use predictive analytics to anticipate the future and make decisions. It comes to the rescue of supply chain leaders, as it helps organizations foresee disruptions, understand the scale of potential damage, and formulate a pre-emptive response to better prepare for future needs.

- This is where predictive analytics comes to the rescue of supply chain leaders, as it helps organizations foresee disruptions, understand the scale of potential damage, and formulate a pre-emptive response to better prepare for future needs.

- Predictive analytics is based on using past data with ML algorithms, neural networks, NLP, time series analysis, and predictive modeling in logistics using techniques like regression analysis and decision trees to know what will be the immediate future.

- Amazon has perfectly used predictive analytics in its supply chain management system. Amazon predicts customer buying behavior through the use of multiple machine learning and big data analytics systems.

- The analysis combines past customer data with seasonal tendencies and economic as well as meteorological elements to maintain correct inventory levels within its warehouses. By implementing this practice, Amazon avoids stock depletion while reducing storage expenses so deliveries function with optimized efficiency.

- Do you know that during COVID-19, Amazon relied on AI predictive forecasting to rapidly handle the unexpected rise in toilet paper sales by 213%? This allowed the company to build market agility through this unprecedented demand surge.

- What it means for organizations is to achieve greater efficiency, cost savings, and risk mitigation in their supply chain operations, forecast future events, detect trends, and identify possibilities and hazards using statistical modeling, data mining, and machine learning.

Open Doors to Efficiency, Agility, and Resilience with Supply Chain Predictive Analytics

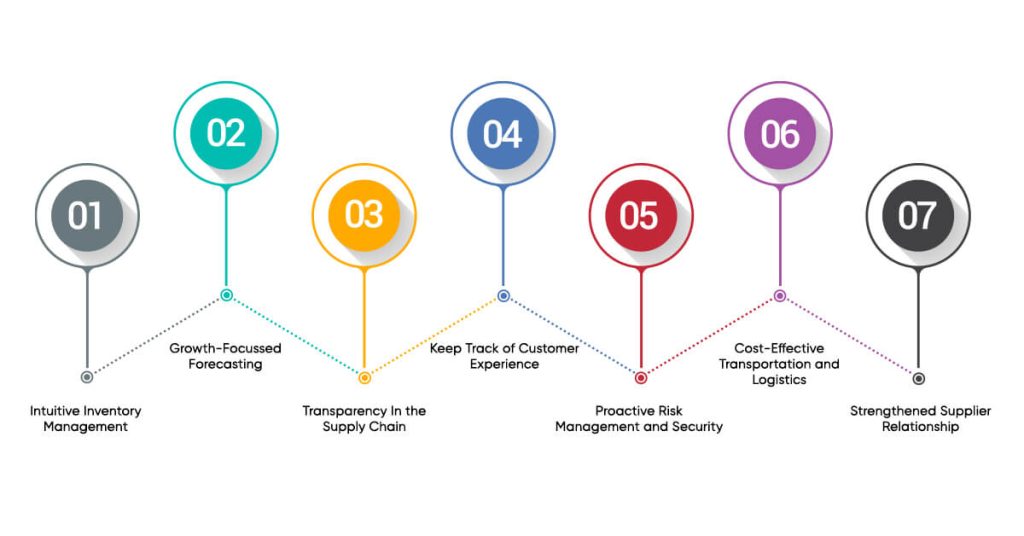

7 Ways in Which Predictive Analytics Transforms Supply Chains

What if your business takes a complete turn where you get high-performing suppliers on board, improve quality, get rid of errors and maintenance issues for good, optimize sourcing, understand the market, and increase your ROI? The benefits of predictive analytics in supply chain management are often overlooked, but the potential it holds is immense.

Do you know the importance of Predictive Analytics in the Supply Chain? Companies invest millions to incorporate technology and data analytics systems in their supply chain to gain benefits.

For example, DHL Supply Chain invested €350 million in Southeast Asia to improve its warehousing capabilities and use modern data analytical systems.

Through this strategic decision, DHL Supply Chain intends to improve resource management as well as automate its workflow processes for adaptable real-time demand changes and economically efficient logistics solutions.

Here’s the role of predictive analytics in logistics and supply chain management:

1. Intuitive Inventory Management

Inventory management is a huge task for growing organizations, and a single miss in the supply chain could result in a domino effect where stock shortages delay production, lead times increase, customer orders go unfulfilled, and revenue losses escalate, ultimately impacting brand reputation and market competitiveness.

“AI assists in creating theft-proof store layouts and product placement,” says Marc Fischer, Dogtown Media LLC

With small business analytics, owners and supply chain leaders can recognize patterns, anticipate demand, and tweak strategy based on seasons and trends. This is a future-focused way to lower costs, remove overstocking or understocking, and bring in sales.

2. Growth-Focussed Forecasting

Most organizations consider data a by-product of their work. However, to become truly exceptional supply chain leaders, organizations need to think ahead. Predictive analytics enables this by using AI in supply chain management, which is competent to analyze past data, compare it with current industry trends, and use multiple other facts, such as market demand patterns, supply chain performance analytics, economic conditions, seasonal fluctuations, and geopolitical influences, for their benefit.

This is a foolproof way to ensure customer satisfaction, eliminate stockouts, and decrease excess inventory by enabling them to match their production, procurement, and inventory management procedures with projected demand.

3. Transparency In the Supply Chain

Have you ever wondered what a foresight into unexpected supply chain disruptions could do for your business? Or what if you could prevent interruptions, avoid costly delays, minimize revenue losses, optimize inventory, and improve supplier reliability while improving customer satisfaction? All this is possible through predictive data analytics services, where AI-driven algorithms, data mining, machine learning, time series forecasting, and optimization models are used to overcome these challenges.

For example, Walmart used DL Freight (a blockchain-based predictive system) to solve invoice issues with its 70 third-party freight partners. The implementation of this system lowered invoice disputes from 70% to less than 1%, which made payments more streamlined.

Also, organizations deploying predictive analytics solutions to interpret geospatial data can further visualize inventory from different store locations.

4. Keep Track of Customer Experience

It is not necessary to get into your customer’s psyche to know what makes them happy or what stands as non-compromisable for them. Predictive data analytics services help organizations understand purchase patterns, feedback, and behavioral data using AI, sentiment analysis, machine learning, and real-time supply chain analytics and data tracking. What this means for companies is proactively addressing issues, personalizing offerings, and optimizing service quality for customized services and recommendations.

For example, through the dynamic, accurate input of data from forecasts, the inventory optimization feature of Amazon helps customers enhance their service levels and fill rates to greater than 92%. This has also enabled them to release up to 20% of capital from overstocked and obsolete items.

5. Proactive Risk Management and Security

Compliance has a huge impact on a company’s success or failure. It’s a touchy subject that can’t be ignored. Companies can use data analytics to keep an eye on production quality. This lets them spot problems, meet compliance rules, and stick to industry standards.

Also, as cyber-attacks keep growing and changing, businesses need to stay alert. Any slip-up could lead to money loss and work disruptions.

But watching everything every minute isn’t doable. That’s where predictive analytics and AI-driven security models come in handy. They find weak spots, watch for fishy activities, and make sure data is protected.

Additional predictive analytics applications in the supply chain include the assessment of macroeconomic indicators, which help make informed procurement and pricing decisions.

6. Cost-Effective Transportation and Logistics

Transportation is an unpredictable ground where disruptions due to vehicle breakdowns, traffic, etc., can delay deliveries and lead to loss of credibility and business. Additionally, rising fuel prices can add to the overall loss. Incorporating predictive analytics in logistics as a core strategy ensures that transportation costs are minimal and deliveries happen on time every time.

Predictive analytics applications in the supply chain ensure route optimization, real-time traffic analysis, fuel consumption forecasting, and dynamic scheduling based on demand patterns.

7. Strengthened Supplier Relationship

Building connections with reliable suppliers is an often overlooked but must-have predictive analytics use case in the supply chain. Supply chain analytics consulting services use advanced technologies to help companies grow supplier relationships by improving visibility, reliability, and collaboration.

Key technologies like ML have an impact on how companies analyze supplier performance data, spot patterns, and forecast potential risks. This helps organizations pick and handle vendors ahead of time. AI makes contract management automatic, and big data analytics consulting gives up-to-the-minute insights into how reliable suppliers are, how prices are moving, and what risks might pop up.

Want to Shift Your Supply Chain from Reactive to Strategic Operations?

Bolstering Supply Chain Efficiency with Predictive Analytics

The above-mentioned benefits of predictive analytics have the potential to upend the way organizations operate and grow. However, fewer than 25% have been able to reap high levels of analytics-driven improvements. Simply implementing predictive analytics doesn’t ensure growth and improvements.

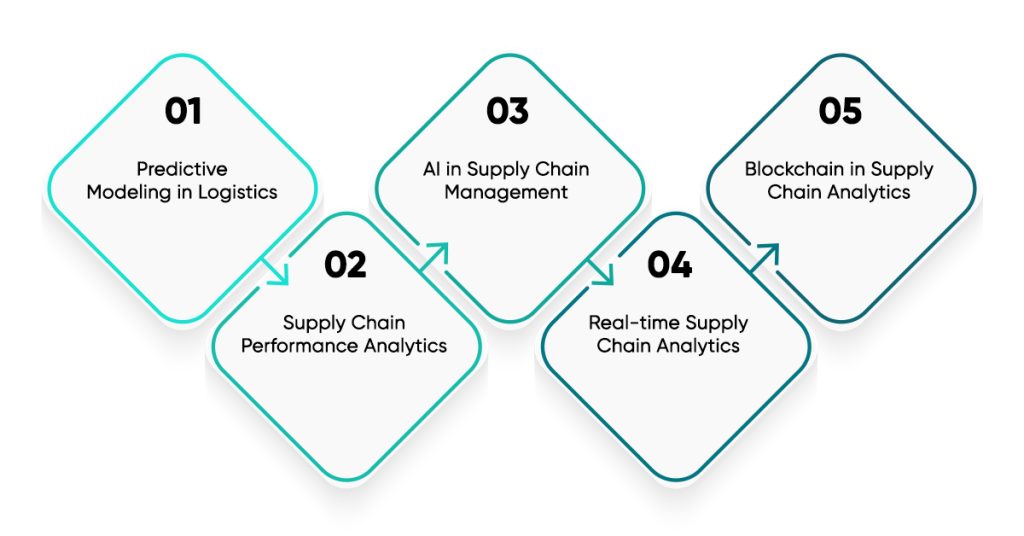

5 Key Differentiators you can achieve by deploying predictive analytics in SCM

1. Predictive Modeling in Logistics

Predictive modeling uses data and algorithms to forecast trends and optimize supply chains. It helps organizations anticipate demand and make proactive decisions through AI and machine learning analysis.

- Enhances forecasting

- Optimizes inventory

- Mitigates risks

2. Supply Chain Performance Analytics

Performance analytics evaluates supply chain efficiency using real-time data and metrics. This helps identify bottlenecks and enables data-driven improvements through predictive analytics and benchmarking.

- Provides operational visibility

- Identifies improvements

- Enables informed decisions

3. AI in Supply Chain Management

AI automates tasks and enhances decision-making in supply chains. It analyzes data to provide insights and improve resilience through integration with IoT and blockchain.

- Automates processes

- Enhances predictions

- Improves resilience

4. Real-time Supply Chain Analytics

Real-time analytics enables swift responses to changes through IoT sensors and cloud computing. It provides instant insights for quick decision-making and optimization.

- Enables rapid response

- Optimizes operations

- Enhances agility

5. Blockchain in Supply Chain Analytics

Blockchain provides secure, transparent tracking of supply chain movements. When combined with analytics, it enables reliable forecasting and risk assessment.

- Enhances traceability

- Improves security

- Facilitates coordination

Wrapping Up

Truly maximizing your investments in predictive analytics means partnering with a company providing exceptional predictive data analytics services with deep domain knowledge, advanced data capabilities, and a proven track record.

Our supply chain analytics consulting is focused on helping organizations transcend boundaries in demand forecasting, inventory optimization, risk mitigation, and supplier collaboration. We work with the vision of empowering organizations with predictive analytics as a service, using business intelligence tools, data-driven forecasting, statistical modeling, and data mining so that businesses can make swift, informed decisions and drive strategic growth with confidence.

We help businesses make the best use of their data by harnessing the full potential of predictive analytics for smarter, more resilient supply chain operations.

Get smarter supply chains with our predictive analytics solutions!

Frequently Asked Questions

Which are the top predictive analytics tools for supply chain management?

Organizations worldwide use SAS Supply Chain Analytics, Tableau, Microsoft Power BI, and Google Cloud AI, which are known for their best cloud infrastructure and advanced machine learning tools. At X-Byte Analytics, we have made long-term strategic alliances with AWS, Google Cloud, and Microsoft Azurso so that you get the benefit of our strong alliances and partnerships.

How can predictive analytics reduce supply chain risks?

Predictive analytics helps companies prevent supply chain disruptions by spotting problems before they happen. It also has an impact on how businesses handle potential supplier delays or demand changes. By looking at past and current data, companies can act to avoid issues.

Can predictive analytics integrate with my ERP system?

Absolutely. Our predictive data analytics services help organizations integrate predictive analytics for logistics with ERP, WMS, and TMS systems to ensure smooth data exchange and real-time decision-making.

Which is better: Predictive analytics or traditional supply chain forecasting?

The problem with traditional forecasting is that it relies solely on historical trends, whereas predictive analytics uses both the power of AI and real-time data, resulting in accurate and dynamic supply chain planning.

What is the cost of implementing predictive analytics in the supply chain?

The costs of implementing predictive analysis depend on the size of your business, software choice, and integration complexity. Broadly, it can fall in the range of $50,000 to $5 million depending on the scope of the project, business needs, scale, and customization expected.