Quick Summary

Industrial analytics is a forward-looking approach adopted by industries in which raw data from industrial operations is collected, analyzed, and turned into an actionable form. Industrial analytics accelerates organizations’ transition to becoming data-driven aligns them and helps them get ahead in the implementation of Industry 4.0 principles. Industrial analytics is a way to automate processes and gain insights into key metrics like reasons for downtime, production status, quality control, energy consumption, and real-time visualization of processes.

Introduction

Industrial operations have come a long way and transitioned from focusing on process efficiency to the implementation of Industry 4.0 through industrial big data analytics. This transition is both an organic and strategic move for future-centric industries that face challenges like the inability to make quick and accurate decisions, data silos, inefficiency in operation, rapidly growing production costs, absence of real-time insights, and an overall non-identification in identifying issues.

This is where industrial data analytics in combination with AI and ML help companies capture the full potential of proprietary and third-party data and bring hidden insights from this data to the fore.

This guide will help industries to understand how they can start incorporating data analytics strategies in alignment with their end goals.

What is Industrial Data Analytics?

Data analytics in industrial applications is akin to a puppeteer controlling the strings of puppets, representing machines, processes, and operations. Similar to how a puppeteer observes and moves the strings to make the puppets act in a certain way, data analytics solutions observe and interpret data from sensors, machines, and systems, and control and optimize industrial operations. Like the puppeteer the role of data analytics is to ensure that every machine moves harmoniously, processes work together efficiently, and there are real-time controls and adjustments if things like machine overheating appear.

For instance, In a car manufacturing plant, sensors collect all the machine data, analyze this information, and help in driving decisions about machine maintenance. So in a nutshell data analytics helps industries pull the right “strings,” at the right time to enable hassle-free operations.

According to Forbes, Industries that are quick at adopting data analytics strategies are set for success and are 19 times more likely to stay profitable and nearly 7 times more likely to retain customers.

Change The Status Quo of Operations with Advanced Industrial Data Analytics Solutions!

Importance of Industrial Data Analytics

Digital maturity is a prime Top management consulting firm, Bains and Company, considers this as an era where industries investing in their data analytics initiatives win. According to Bains and company, industries can harness the power of industrial analytics solutions to achieve quality while earning a substantial return of 15-20% from their data analytics investments.

Industrial analytics solutions coupled with Generative AI are effective instruments for eliminating operational disruptions, economic losses, and inefficiencies while enhancing productivity, improving decision-making, and optimizing resource allocation.

|

“Without big data analytics, companies are blind and deaf, wandering out onto the web like deer on a freeway”

|

Industries using data analytics achieve higher operational efficiency, quality improvements, cost reduction, predictive insights, and supply chain optimization. C-suite leaders in the oil and gas, manufacturing, semiconductor, healthcare, insurance, finance, retail, energy, telecommunications, and automotive industries can combine data from various disparate sources and create synergy while taking care of cybersecurity concerns through secure and scalable cloud-based industrial analytics solutions.

How Industrial Data Analytics Service Providers Catalyze Growth?

A recent report from Statista highlights that around 64% of respondents to its survey stated that using data and analytics, improved efficiency and productivity for their companies. Insights from Boston Consulting Group further second the need for adopting a structured data maturity framework that involves a strategic roadmap involving data collection and analysis that can help companies harness the potential of industrial data

What do Industrial Data Analytics Service Providers Offer?

Companies with a proven track record, experience, and deep domain knowledge in data analytics help industries incorporate industrial analytics strategies and develop industrial analytical capabilities. They help companies move beyond fragmented data strategies where value lies on the table and achieve a revamp of the entire industrial ecosystem where benefits like productivity, predictive maintenance, and quality control are just starters.

1. Cloud-Based Industrial Analytics Solutions

Companies looking to achieve data transformations can benefit by moving their legacy systems to the cloud. Cloud-based industrial analytics services help companies move ahead from the continued battle with data silos, legacy systems, and distributed data sources. Industrial analytics consulting companies help industries through advanced data analysis tools and capabilities on the cloud platforms.

These cloud platforms help businesses to scale when their business grows in addition to providing access to on-demand industrial analytics tools, scalable data warehouses, and data lakes to manage high-volume datasets, data cleaning, analysis, and visualization tools, ML-powered analytics tools and integration with industrial Internet of Things (IIoT) and business channels, BI, and visualization tools.

2. AI-Powered Industrial Analytics Services

Industries can benefit by integrating elements of advanced analytics (AA) and AI to add efficiency to process models as highlighted by McKinsey. AI-powered industrial analytics services help in data collection in real-time data from industrial sensors, machines, etc., and facilitate data processing and cleaning using ML models like regression, classification, and anomaly detection to identify patterns, trends, and anomalies within the data. It also helps in forecasting potential equipment failures before they occur, process optimization, and anomaly detection.

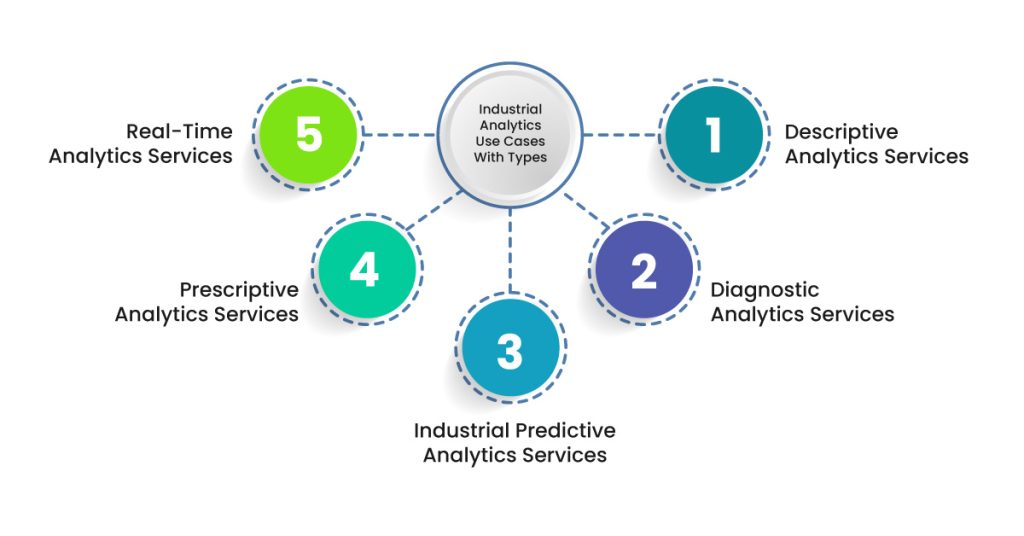

Industrial Analytics Use Cases With Types

Data and analytics consulting service providers develop advanced data analytics for factories and smart factory solutions using AI-powered industrial analytics so that companies can stay ahead of the curve, drive cross-functional collaboration, and use their new-found industrial analytical capabilities as an innovation catalyst for new product development.

These industrial data analytics solutions for smart factories help organizations in retail, finance, manufacturing, pharmaceutical, automotive, and others use them to their advantage.

1. Descriptive Analytics Services

Do you want to turn the large volume of proprietary data that lies unused in disparate systems into some solid insight for business growth? Descriptive analytics helps you do exactly that. It interprets this data, understands the trends, and provides key insights on the next course of action. Usually, it uses data like production outputs, patterns in operations, and reports to evaluate the performance and key visualizations in the form of dashboards, charts, and graphs for strategic decision-making.

Use Cases of Descriptive Analytics Services

- Production Tracking: Largely for monitoring and tracking production efficiency and preemptively identifying bottlenecks in industrial workflows.

- Performance Reporting: Used to create in-depth reports for stakeholders to review operational outcomes.

- Inventory Analysis: Helps in tracking inventory levels and maintaining stock to meet demand.

2. Diagnostic Analytics Services

What went wrong and why is often a constant query in manufacturing processes, especially when productions stall and downtime is massive. What if this can be predicted in advance? Diagnostic analytics services are used to identify the root causes of specific events in industrial processes and are used to uncover why something occurred, thus enabling the addressing of issues effectively. It uses a combination of data mining, correlation analysis, and drill-down techniques to provide deeper insights into challenges.

Use Cases of Diagnostic Analytics Services

- Downtime Analysis: Get an edge in identifying causes of unplanned equipment failures and improve maintenance schedules.

- Quality Control: Find defects and discrepancies in products and pinpoint contributing factors in production.

- Supply Chain Bottlenecks: Analyze the pertinent delays and inefficiencies in supply chain operations.

3. Industrial Predictive Analytics Services

What happens if you have insights into past operations and a vision of what the future can bring for your industrial operation? Industrial data analytics for predictive maintenance are the most used type of industrial data analytics solutions where future forecasts and outcomes are determined using historical and real-time data. This is made possible through ML algorithms and statistical techniques and helps in reducing downtime and boosting productivity.

Use Cases of Predictive Analytics Services

- Predictive Maintenance: It helps in getting insight into equipment failures and facilitates proactive maintenance.

- Demand Forecasting: This helps devise a strategy to never fall short of promises on deliveries by predicting market trends and historical sales data.

- Energy Usage Predictions: Sustainability is the buzzword and predictive analytics solutions help in anticipating energy consumption patterns and optimization of resource allocation.

4. Prescriptive Analytics Services

What if you get expert advice on the strategizing you need to adopt for better operations? Prescriptive analytics is your expert solution where actionable recommendations are provided so that industries can optimize industrial processes and outcomes, by combining predictive insights with optimization models to guide decision-making. This is made possible through the integration of advanced algorithms and simulation techniques for the determination of the best course of action under specific conditions.

Use Cases of Prescriptive Analytics Services

- Production Optimization: It is best used for recommending adjustments that help achieve maximized outputs while minimizing waste.

- Inventory Management: It finds best use in maintaining optimal inventory levels through suggestions and thus balancing demand and supply.

- Logistics Planning: It is a strategic way to identify the most efficient transportation routes to reduce delivery times and costs.

5. Real-Time Analytics Services

Just working over the past and future data from machines and systems can’t help you win present-day battles. Real-time analytics services take you directly to what is happening in the now and provide actionable insights at the moment. It is crucial in industries where immediate responses are required, such as manufacturing, logistics, and energy. It is a complex process that involves continuous monitoring of data streams, enabling organizations to detect anomalies and adjust operations promptly.

Use Cases of Real-Time Analytics Services

- Operational Monitoring: This finds applications in every industry where keeping track of machine performance and resolving issues is needed.

- Energy Management: This is a key future-focused strategy involving monitoring energy consumption in real-time to prevent overuse and reduce costs.

- Process Automation: The immediate use case that finds massive use is the immediate adjustments that can be made through automating workflows.

Get ahead in the Industry 4.0 era with powerful industrial data analytics!

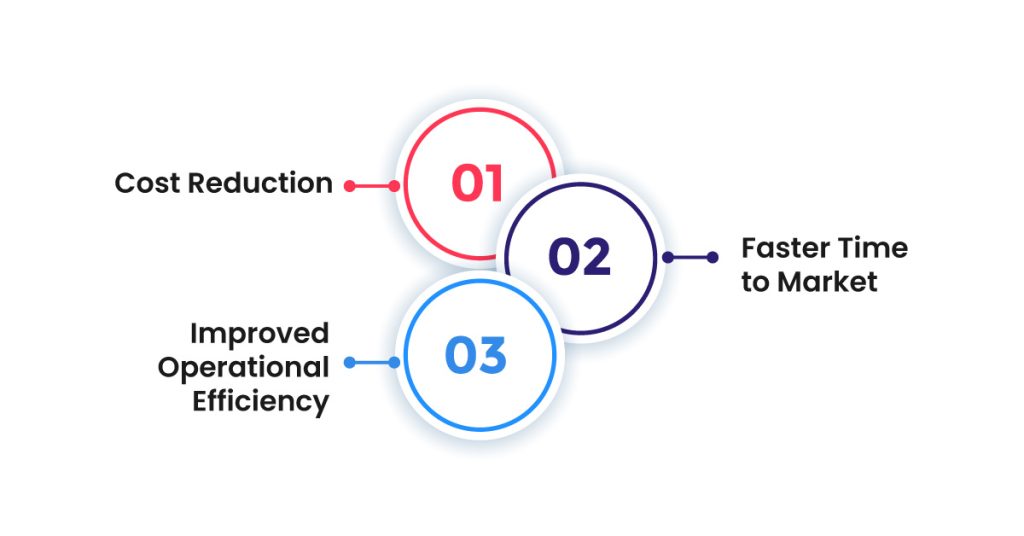

Top Benefits of Industrial Data Analytics

According to McKinsey data and analytics represent a 20% growth opportunity and the companies who have adapted it have a front-runner’s edge over those on the fence.

Let’s discuss the key benefits of industrial data analytics:

1. Cost Reduction

Data analytics can play a huge role in improving procurement, maintenance, and operational activities. These data-driven efforts can help industries to identify savings by optimizing indirect spending. Additionally, analytics capabilities can enable organizations to save enormously on material procurement costs, which can then translate to significant margin improvements. In fact one of Bains’s strategies “Buy Better + Spend Better” involves using complex analytics as a way to reduce purchasing cost base by an average of 8-12% plus an additional 2-3% savings annually!

2. Faster Time to Market

The role of data analytics in industries is not limited to automating operations or achieving higher ROI. It is about achieving considerable savings on the most important asset i.e. time. This involves time used by manpower, machine, and C-suite leaders. When data and analytics become part of the industrial ecosystem it improves reporting and data visibility, and companies can speed up product development cycles and time to market, and reduce invoicing time, allowing faster revenue realization and better cash flow management.

3. Improved Operational Efficiency

Data analytics combined with AI can expedite operations in manufacturing and industrial settings. Additionally, process mining and data visualization tools when used strategically can reduce overhead costs and processing time, freeing up resources for more value-adding tasks.

Future of Industrial Data Analytics

Data-centric approaches are taking center stage and organizations need to buckle up to adapt or risk falling behind. that aim to revolutionize operational efficiencies across industries. Top consulting firms like Gartner have time and again highlighted the critical role that “sense-and-respond” strategies involving data, analytics, and AI will play in driving digital growth, emphasizing the need for robust strategies to accelerate automation and reliability.

Companies must take a calculated leap of faith by partnering with data and analytics service providers to embrace the best practices of incorporating data and analytics across all touchpoints. A reliable data industry data and analytics company can ensure that your data infrastructure is ready to predict machine failures, reduce downtime, reduce costs, and improve risk management.

Conclusion

Though the statistics are in favor of implementing data and analytics for achieving success. Companies remain latent in adopting these strategies and those that do adopt data and analytics fall short of being “data-driven” by far. These organizations need to move away from making sporadic data and analytics integration as a lack of structure in incorporating data analytics frameworks can create additional bottlenecks and inefficiencies.

X-Byte Analytics is a partner of choice for industries looking to level up their data analytics efforts for sustained success. We use big data, AI, advanced analytics, and data visualization to bring hidden opportunities to the fore so that results from data and analytics initiatives are visible in operations and balance sheets.